Products

An optical material that combines excellent optical performance with a wide range of options.

Thanks to its excellent optical properties, “Iupizeta EP” is used as a high-performance precision lens material for smartphones and various optical devices. With its unique combination of a high refractive index, low birefringence, and high heat resistance, it has been gaining attention as a material that meets a wide range of product needs.

Product Lineup (Major Grades)

| Grade | Refractive Index (nd) | Abbe Number (νd) | Glass Transition Temperature(Tg)[℃] |

|---|---|---|---|

| EP-4500 | 1.616 | 25.8 | 145 |

| EP-5000 | 1.636 | 23.9 | 145 |

| EP-6000 | 1.640 | 23.5 | 145 |

| EP-8000 | 1.661 | 20.4 | 140 |

| EP-9000 | 1.671 | 19.2 | 140 |

The listed properties are portrayed as general (measured) information only and are not guranteed specifications.

Mitsubishi Gas Chemical disclaims any liability in connection with the use of the information in this table

Key Features

High Refractive Index

Compared with conventional standard polycarbonate resins (nd 1.58), we offer high-refractive-index grades (up to nd 1.68). We are also developing grades with even higher refractive indices. By increasing the refractive index of lens materials, we can, for example, minimize smartphone camera bumps (protrusions) to the greatest extent possible, enabling more refined.

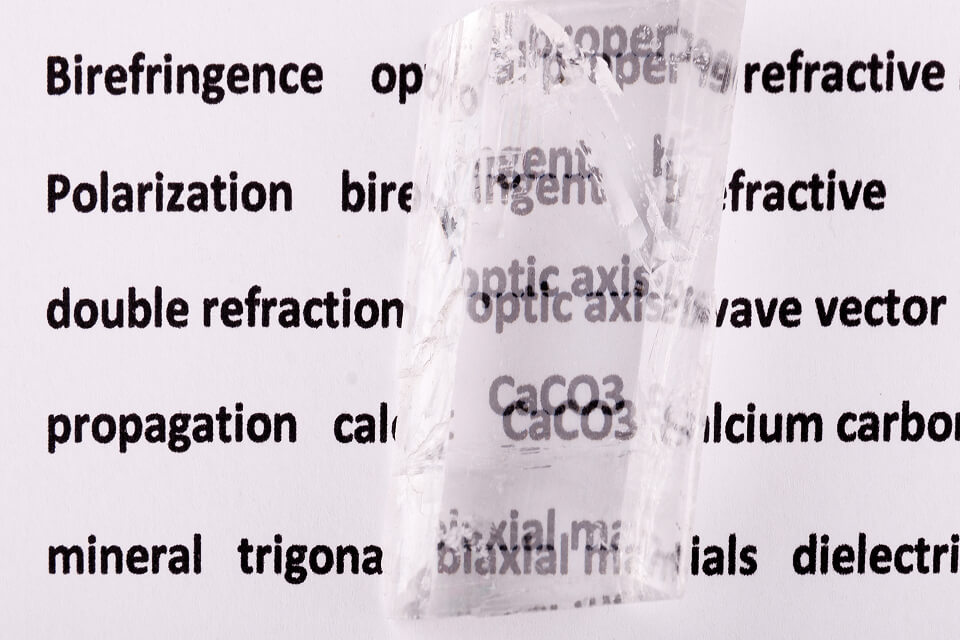

Low Birefringence

Birefringence is a phenomenon in which images seen through a lens appear doubled or blurred. In today’s optical devices, where high-definition visual experiences are expected, controlling birefringence is a critical challenge. Through specialized molecular design, Iupizeta EP has succeeded in minimizing birefringence. It eliminates “image blur” and “rainbow interference fringes” that were unavoidable with conventional resin lenses, delivering an unprecedentedly clear and immersive viewing experience.

Heat Resistance

Thanks to its excellent heat resistance, Iupizeta EP is also used in in-vehicle cameras. We are also developing ultra-high heat-resistant materials compatible with reflow soldering, a process in which allows for lenses to remain mounted while directly being soldering to the circuit board.

Iupizeta EP Asset

- Optical Performance

-

High Refractive Index

By strongly bending light with a high refractive index, it enables ultra-thin lenses and higher performance.

Low Birefringence

With proprietary molecular design that minimizes refractive-index anisotropy to the utmost, it delivers sharp images without color fringing.

Refractive Index Dispersion (Wavelength Dependence)

By enabling control of wavelength dispersion, it can deliver vivid and accurate color reproduction.

Wavelength Selectivity

From visible light to near-infrared wavelengths for sensing, it can selectively transmit only specific wavelength ranges according to the application.

- Physical Properties

-

High Heat Resistance

Excellent heat resistance prevents deformation even in high‑temperature environments, supporting harsh conditions such as in‑vehicle cameras.

Flowability

With excellent resin flowability, even thin lenses and complex, fine geometries can be molded precisely as designed.

Dimensional Stability

By suppressing expansion and contraction caused by environmental changes, it can maintain stable performance over the long term.

Lightweight

With optical properties comparable to glass and a low specific gravity, it helps reduce device weight.

- Manufacturing & Environment

-

Material Development

We can develop and deliver materials in as little as about one month from your request.

Mass Producibility

Leveraging the advantages of thermoplastic resin, mass production with ease through injection molding.

Technical Support

To help solve your challenges, we can also provide technical data and offer on-site support at your molding facilities.

Sustainable

Through low-environmental-impact manufacturing processes and material development, we contribute to a sustainable society and the advancement of optical technologies.